Looking for the most researched and tested subwoofer solutions for your GTR? Experience matters and with over 8 years of developing and refining GTR specific enclosures, we have come up with solutions for all audio goals and budgets. Whether you are looking for a 10″ stealth box, the highly regarded Twin 8″ setup, the powerhouse Twin 10″ setup, or an entirely custom one-off solution, we can make it happen.

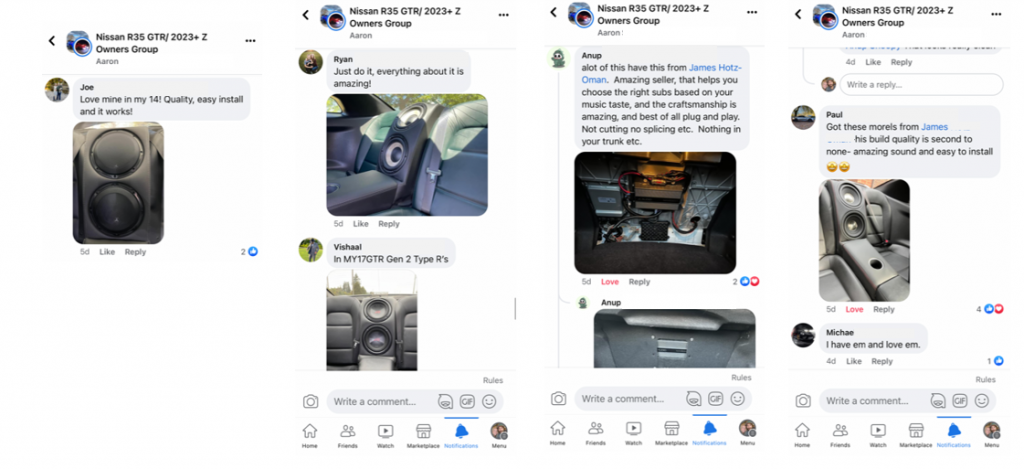

Already familiar with our systems and would like to contact us or purchase a system? Please reach out or click the links below for additional product specific information. As a specialty business, we not only offer the best quality enclosures, but some of the best customer service available.

Why the Factory Bass is Underwhelming

The R35 GTR is an iconic supercar with a long-standing history of being an incredibly fast production vehicle. One shortcoming however, is that the factory stereo system does not measure up to the GTR standard of high performance. In fact, in many cases the bass provided by the factory GTR audio system is difficult to hear over any aftermarket exhaust. You may wonder why the bass is underwhelming because the factory subwoofer box looks like a large and somewhat impressive housing with Bose subwoofers. In reality, the factory subwoofers are free-air bass drivers that are 2″ in depth that vent into the trunk. The small size, poor factory enclosure specification, and minimal excursion of the subwoofers prevent them from being able to produce the volume or quality of bass that you would expect.

Why Xtreme Audio Systems Sound and Perform so well

Xtreme Audio systems are special because of the research and testing that goes into each setup. These systems are not simply about the box or subs, but how the entire system comes together as a whole. This requires a focus on the box specifications, mounting solution, construction quality and general system engineering to result in a solution that sounds and looks excellent while being easy to install. Believe us when we say that we have tested every combination of subwoofer size, placement and power level because we have. Put simply, we know what works and what does not. We also know how to troubleshoot and provide assistance any audio related issue.

Enclosure Design: Every curve, angle, and measurement are by design with the goal to produce a spec volume, highly rigid, and air tight enclosure that sounds as good as possible.

Rigid Mounting & Connections: Enclosures are firmly mounted to the vehicle to prevent any movement or vibration created by the subwoofers. Threaded T-nuts or direct enclosure mounting slots are built into each box to secure the enclosure firmly without the use of screws. High-quality terminal cups are used to ensure there are no cracks or air leaks and that the amplified power reaches the subwoofers with minimal resistance. Enclosures are wired up with 14 gauge oxygen free pure copper wiring with all connections being soldered. BlackHole stuff is also added to improve the sound dynamics of the enclosures.

Construction Quality: The level of quality of these enclosures is only possible through the use of the best possible equipment such as SawStop, Bosche, CNC machines, precision jigs and custom made shop air filtration. This may seem insignificant, however quality tools and the best safety practices lead to a much higher quality end product. All enclosures are made in small batches to ensure that equal time and care is invested in each box. Like a handmade car, these enclosures are built with the passion and care that you could expect from a premium product.

Testing, Packaging, and Shipping

Prior to shipping prep, every component of every system is tested on a bench test simulator. This ensures that everything is assembled correctly and sounds as it should. Systems are not mixed and matched during the testing phase. This means that for plug and play systems, your amplifier will be paired with your subwoofers for the test to ensure proper working order. The bench simulator is setup to test full systems, amplifiers, subwoofers, speakers and crossovers. In short, nothing leaves the shop without first passing the bench test.

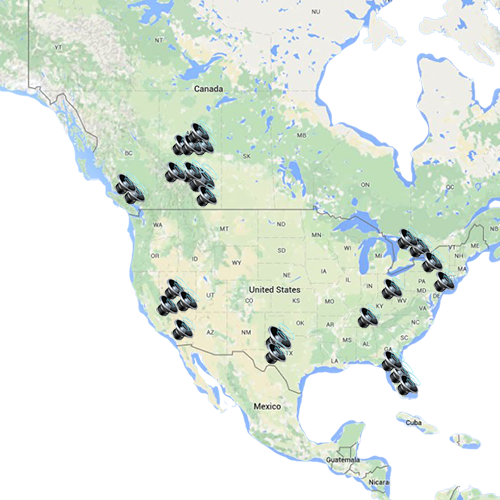

We sell our GTR subwoofer systems globally. Systems have been shipped to clients located in Canada, United States, United Kingdom, Germany, China, Sweden, Australia, and Thailand. Since we ship these systems globally, we take packaging very seriously. Shipping boxes are double walled cardboard boxes rated for a drop weight of more than triple the shipping weight of the system. Additionally, a generous amount of packing materials are used for each shipment. It takes an hour to pack each system to our standards. Here is the packing process for all enclosures or systems leaving our shop:

- Clean all system parts and wrap in plastic bags.

- Line enclosure edges with 1/8” foam.

- Encase the enclosure and power supply (for plug and play system) in 1/2×12” bubble pack.

- Cover the subwoofers and rear of the enclosure in 1/8” cardboard to protect the drivers and rear of the box.

- Pack items in the larger double walled shipping box using the air pillows for large voids and packing peanuts for smaller voids.

- Seal the box with industrial grade tape and apply the appropriate “Fragile” and “This Side Up” universal packing labeling.

- Ship via Canada Post Xpress air for speed, safety and cost savings compared to private carriers (FedEx, UPS, DHL, etc.)

Packing to this level is an expensive, time consuming, and tedious process, however it is necessary to ensure that the system arrives to you in the same condition it leaves the shop. Delays or potential damage during the shipping process is outside of our control, however we do everything possible to minimize those risks. To date, many full plug and play GTR stereo systems are creating high-quality and crisp sounding bass for customers at home, and internationally. The location of some of our systems sold in North America can be seen in the map below:

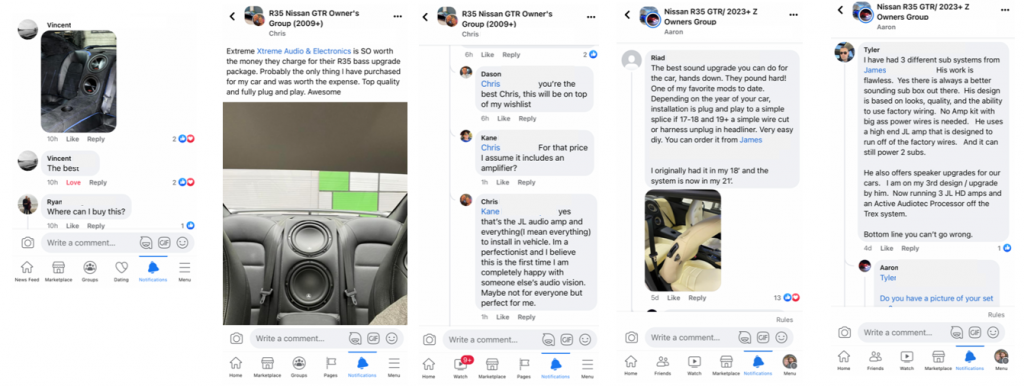

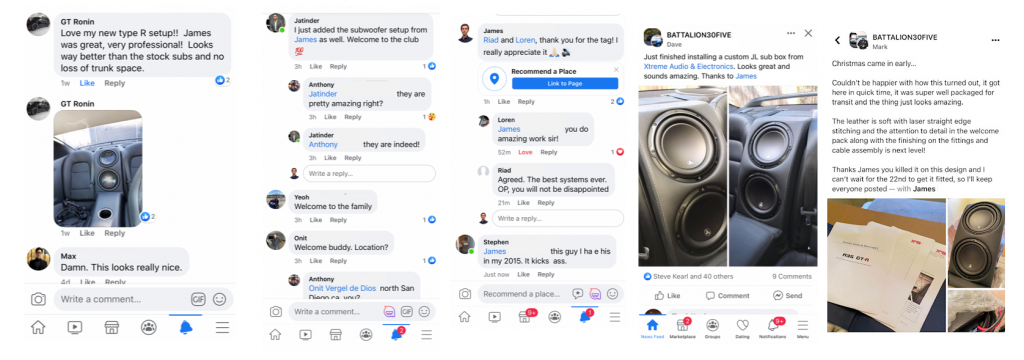

Customer Reviews

Frequently Asked Questions

- Q: How much bass does this system really add?

- A: The Twin 8 adds is approximately double the bass output of the factory depending on your settings. This system also reaches far more of the bass spectrum when compared to the factory subwoofers. The Twin 10 adds approximately four times as much bass as the factory subwoofers.

- Q: Does the added bass overpower the factory speakers and will I need to upgrade my speakers?

- A: No, the new subwoofers actually compliment the factory speakers very well and there is no need to upgrade your speakers.

- Q: How much does the system weigh?

- A: The total system weight depends on the subwoofers you go with. The twin Alpine R curve plug and play is the heaviest system and comes in at 32lb (14.5kg).

- Q: I have no experience working on cars, is this something I can really take on myself and how long will the install take?

- A: The install is very simple for 2009-2014 cars. Even if you have no experience, you will finish the install in under two hours. If you have a 2017+ GTR, there are a few more steps and it is common for the install to take 3.5 hours if you have no experience.

- Q: How is your customer service? If I have problems or questions can I reach out to you?

- A: Customer service is taken very seriously. Our response time during the day via email is typically under one hour. We respond to emails 7 days a week.

- Q: How fast is your shipping and why is it a fixed rate?

- A: Shipping within North America is typically 6 business days. Please note that shipping times during COVID-19 are somewhat variable and are outside of our control. Shipping times for locations outside of North America are also typically longer.

- Q: Is there a way for me to get my subwoofer upgrade faster?

- A: Absolutely, if we have the system you would like in stock we can arrange different shipping methods to get the system to you in 2-5 business days using priority air shipping.

- Q: Is there a return or refund policy?

- A: There is no specific policy and requests are treated on a case by case basis. Generally, refunds are not provided for used equipment, however, if there is an electrical failure in your system, please do reach out and we will do our best to remedy the situation. Please note that each component of the system is tested during assembly, and as a whole once complete prior to shipment. From 2017 to present, there have been no system issues resulting in replacements or refunds.

- Q: I have decided that I would like to purchase a system, how do I go about doing this?

- A: The best way is to simply contact us. We will ensure that the proper equipment is sent out to you at the best price. All payments will be arranged using PayPal and the invoicing will be managed on our end. After the purchase we followup with the tracking information, when the system has been delivered, and after you have installed the system.